Hengxin Printing Equipment Co., Ltd.

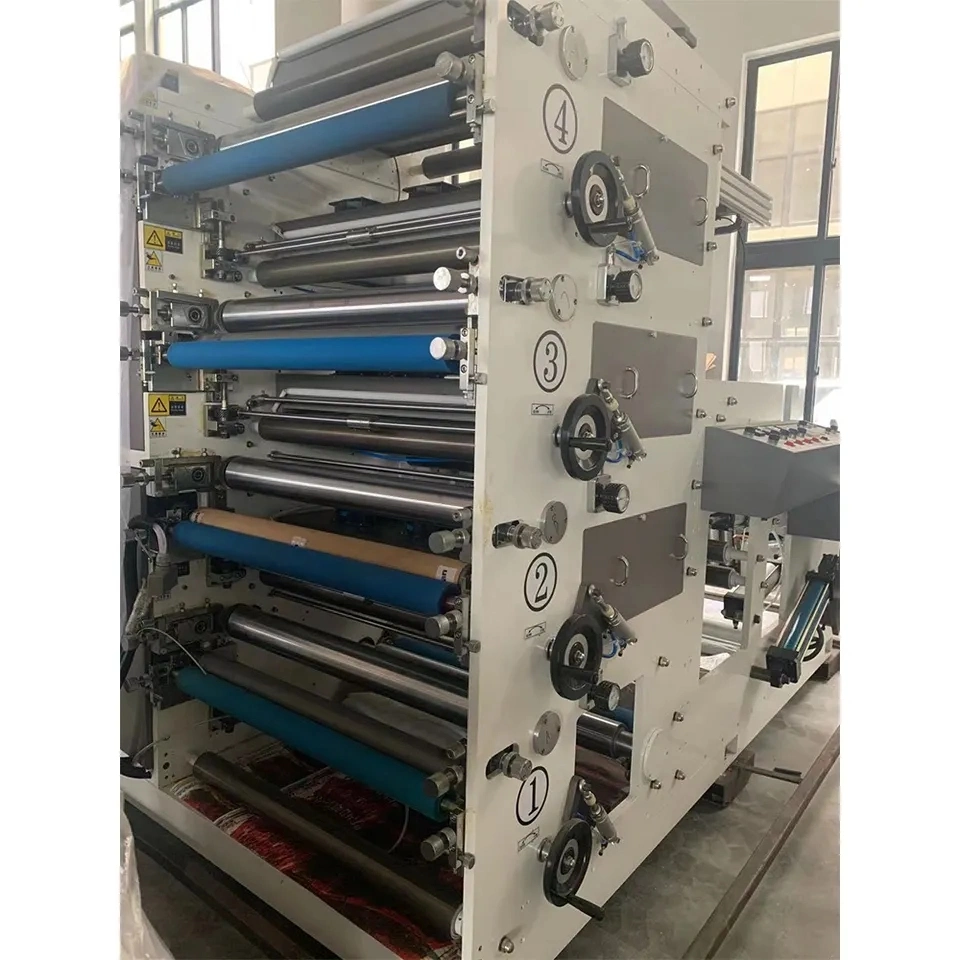

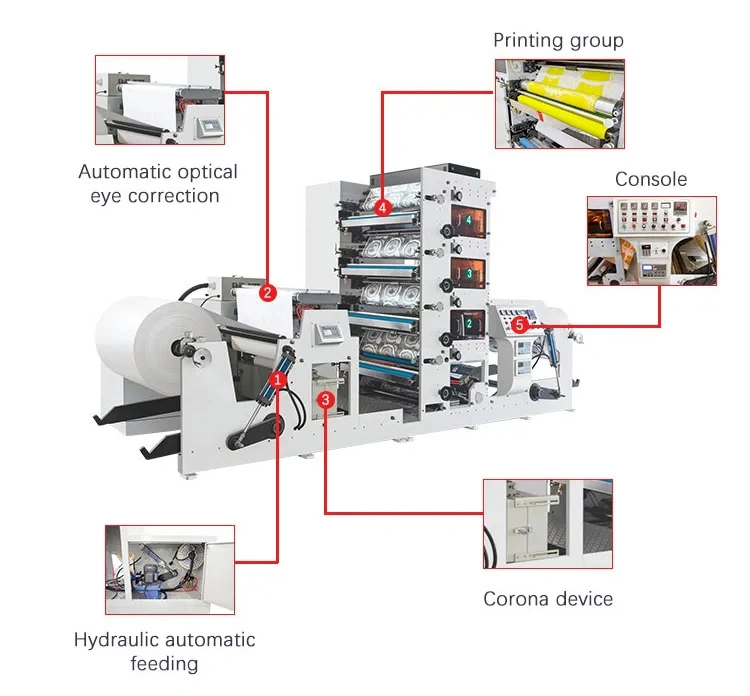

Flexographic Printer Printing Machine Paper Cup Paper Bowl Flexo Printing Machine

Hengxin Printing Equipment Co., Ltd.

Basic Configuration

Product Description

paper cup flexo printing machine.

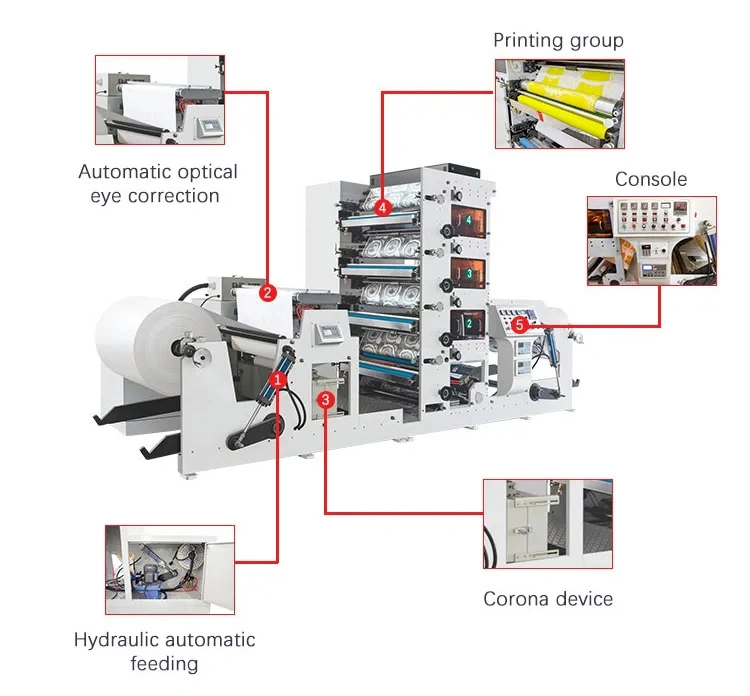

1.The main motor adopts imported stepless frequency control.

2,Feeding and discharging device are controlled through magnetic powder brake and clutch

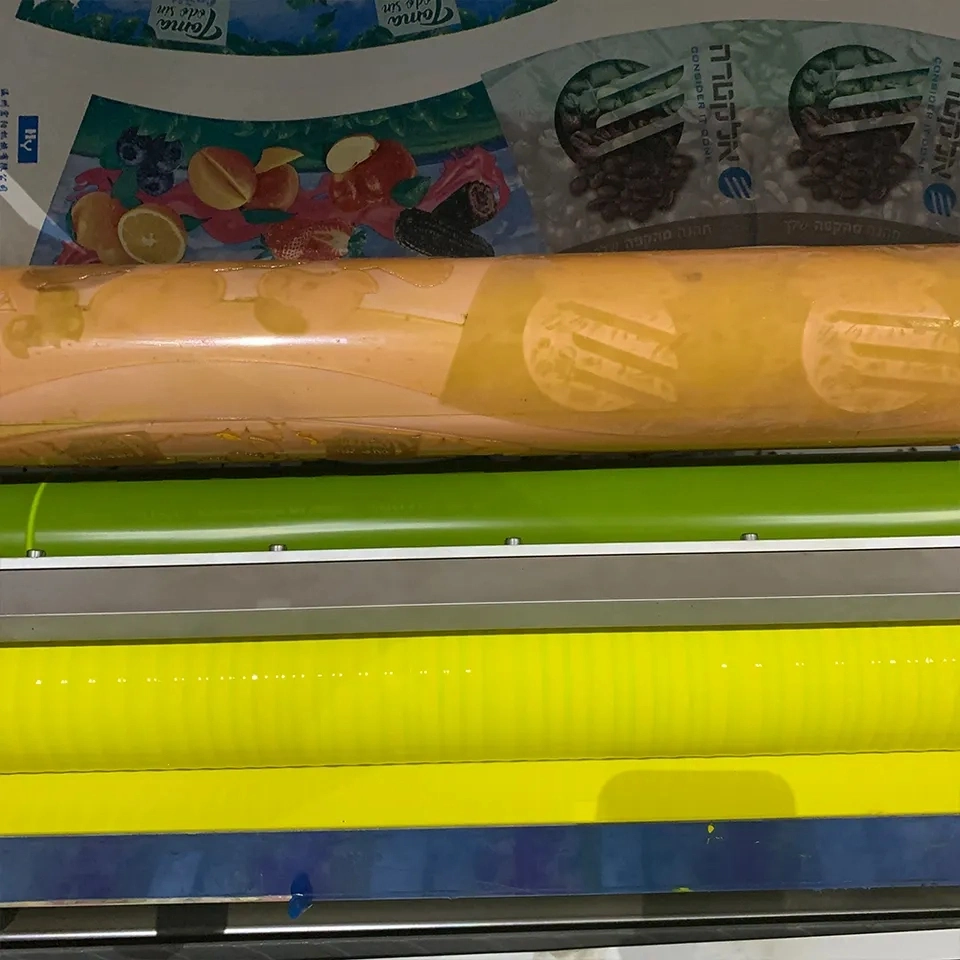

2,Feeding and discharging device are controlled through magnetic powder brake and clutch

(Japanese Mitsbish aut tension controller).

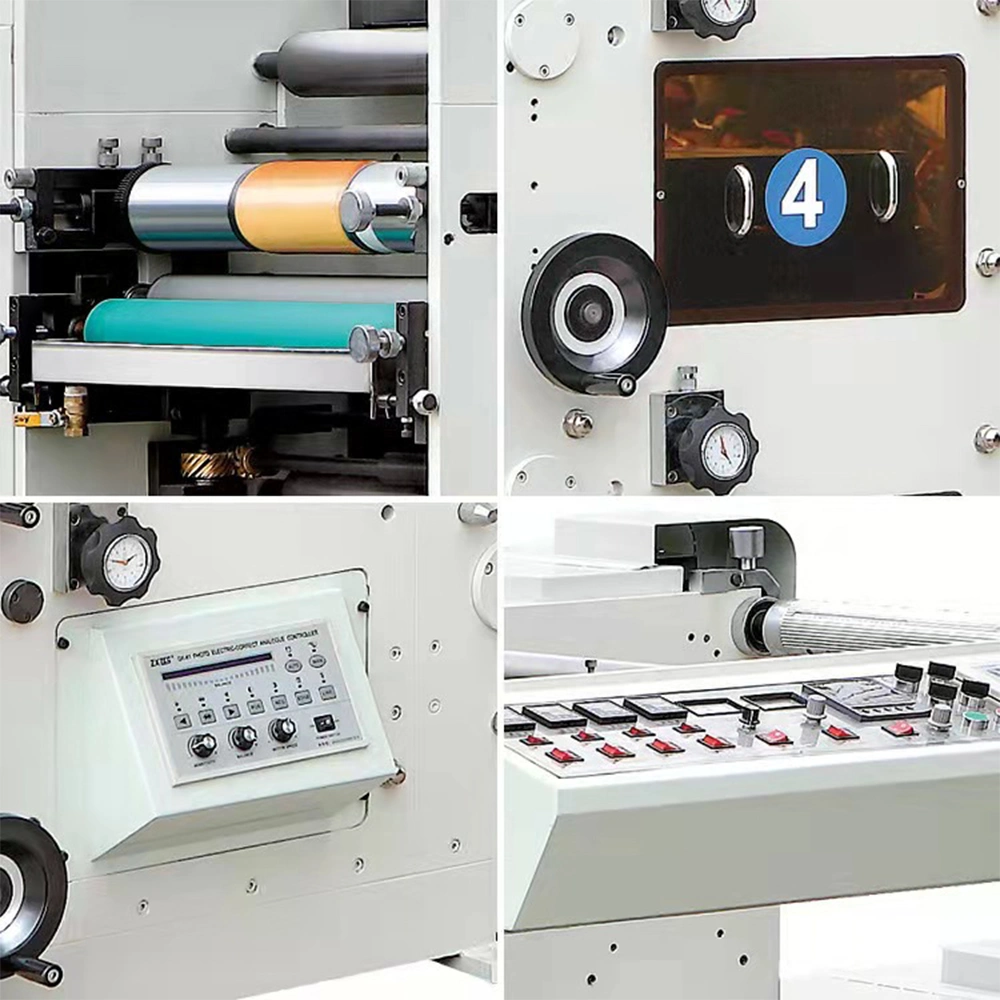

3,Adopt ceramic mesh distrnic mesh distributor roller,which is durable,wear proof,corrosion resistance.

3,Adopt ceramic mesh distrnic mesh distributor roller,which is durable,wear proof,corrosion resistance.

It is favorable to reduce the replacement frequency of mesh roller and improve the printing efficiency.

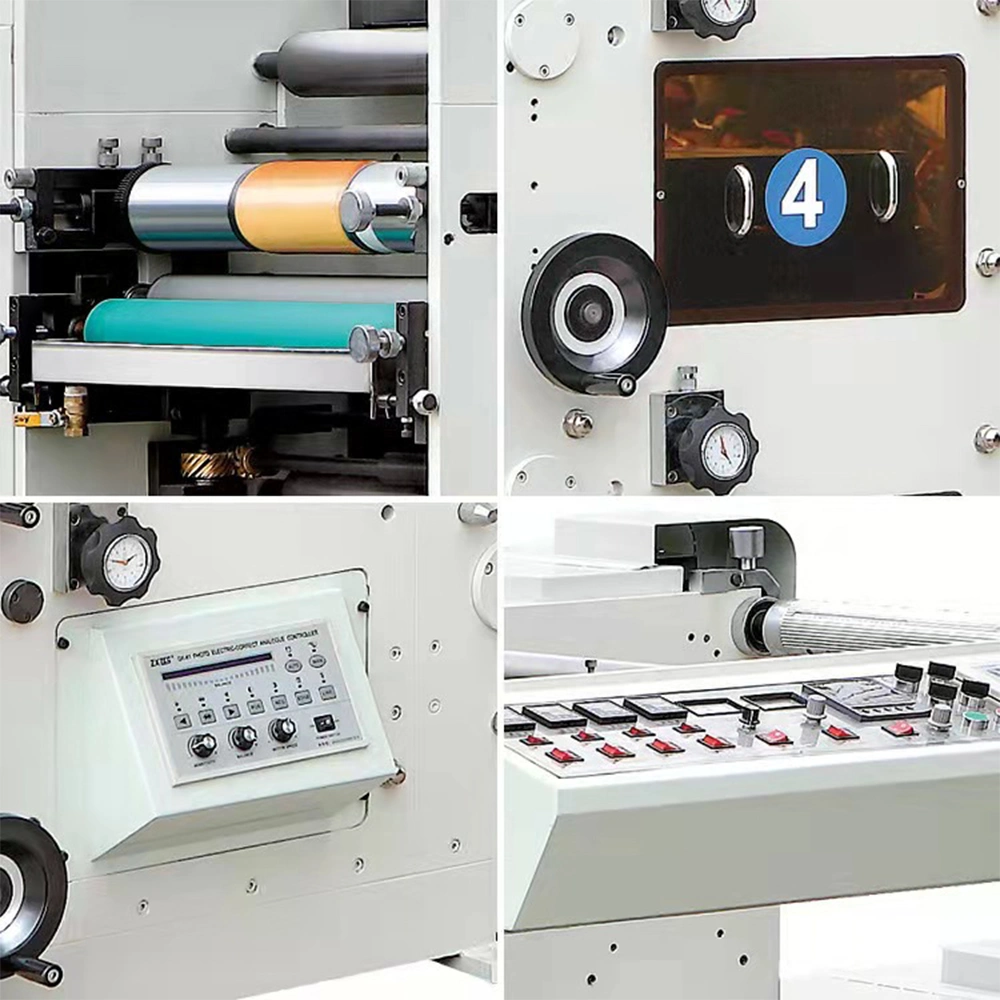

4,The printing unit can register in 360degress;each printing unit can mesh roller and improve the printing efficiency.

5,Every printing unit equipped with a group of infrared dryers respectively.

6,The redding and discharging device use air-expansion core shaft.

7,The inking roller can automatically fall off at stoppage and ratate at low speed in order to keep the ink from being dry and solid.

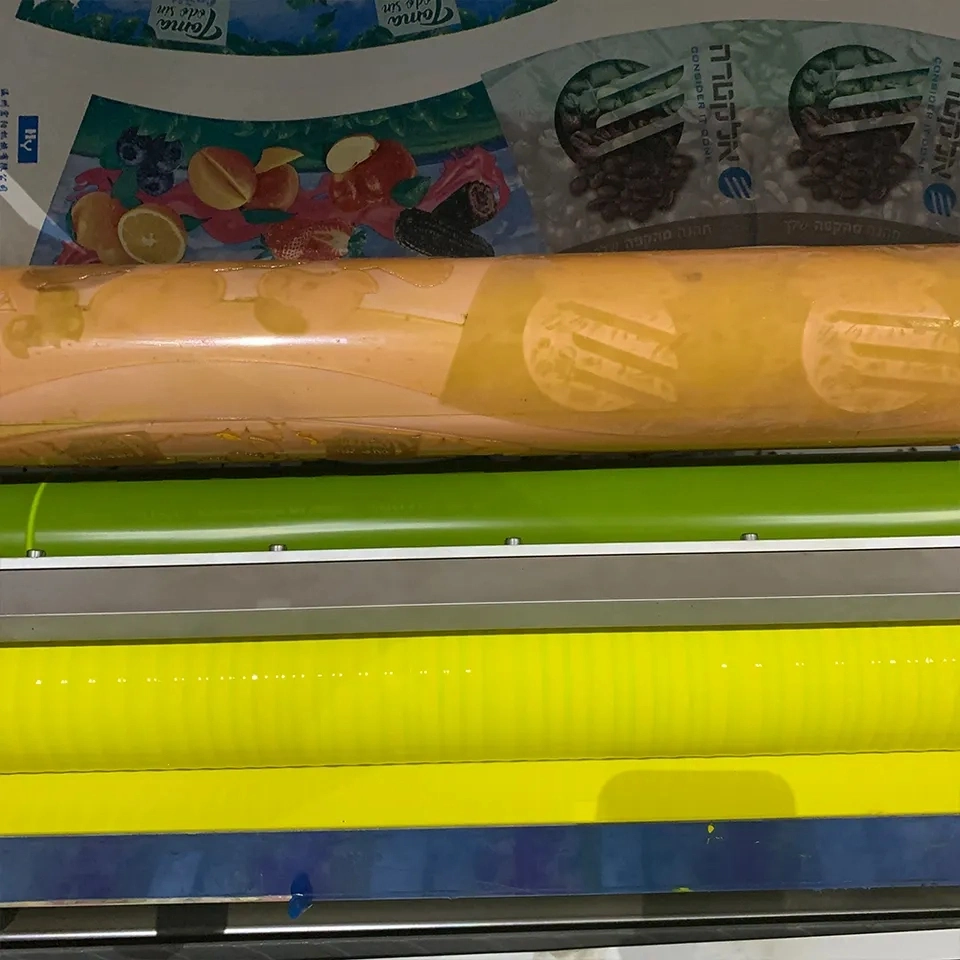

8,The roll feeding,printing,polishing,auto infrated drying,laminating and rolling can be processed in one processing.

9.It features wide application,pollution-free of printing ink,high economic benefit,and high printing speed.

4,The printing unit can register in 360degress;each printing unit can mesh roller and improve the printing efficiency.

5,Every printing unit equipped with a group of infrared dryers respectively.

6,The redding and discharging device use air-expansion core shaft.

7,The inking roller can automatically fall off at stoppage and ratate at low speed in order to keep the ink from being dry and solid.

8,The roll feeding,printing,polishing,auto infrated drying,laminating and rolling can be processed in one processing.

9.It features wide application,pollution-free of printing ink,high economic benefit,and high printing speed.

So it is an ideal printing machine for the commercial bill,paper card,and high-class free adhesive label.

Basic Configuration

- One set of Feed roll unit

- One 3inch air swelling shaft can change 6inch air swelling shaft

- Auto tension control system of unwinding and rewinding, one Magnetic powder brake ( Mitsubishi Japanese).

- Fast inflating gun

- One set of EPC control system

- One set of Paper binding table

- The paper guide roller adopts high hardness anodized

- Adopt the ball screw electric actuators

- Adopt rectifying photoelectric head to rectify induction

- Electronic paper web guide traction device, there was a small offset paper web movement, the system can accurately continuously revised

- Closed-loop control system

- Test method: edge

- Rectification precision:±0.12mm

- One set of Adjustable feeding paper system (Dual pressure roller)

- Dual pressure roller pressure feeding together

- Printing paper tension adjusted

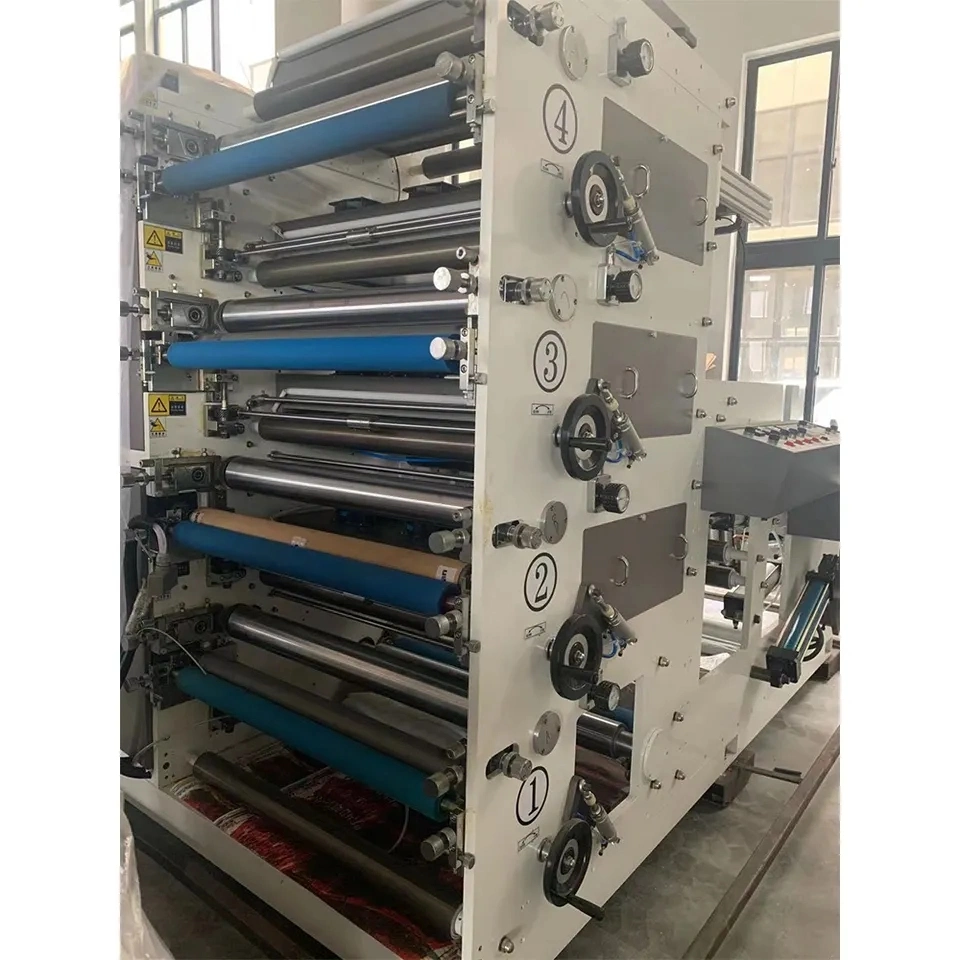

- Four Color printing unit

- The printing unit adopt 45 degrees of DP13 helical gear structure

- Reserved image detection station

- Net roller, version roller pressure pneumatic clutch

- Ceramic net cable roller (as require)

- Plate cylinder 4pc .(as require)

- Manual transverse focusing alignment 4 set

- Manual vertical focusing alignment 4 set

- Single pole reverse scraping system 4set

- Stainless steel cartridge 4set

- Fast changing plate cylinder without any tools

- Net roller rotation function: every time when stop network roll automatically, prevent ink roller surface dry solid, the network cause net hole plug.

- The gear stick:cp1/8

- Dryer (one set)

- Infrared heating drying printing unit,IR 4set

- One set of the rear paper tension system

- one set rewinding system

- A set of winding for rewinding after printing, with One 3inch air swelling shaft can change 6inch air swelling shaft

- Max rewinding diameter 1400mm

- Installed version machine (one set)

- On the ordinary version machine, including bilateral symmetry points and 10 times the magnifying glass

- For version, in order to achieve multi-color overprint accurately

- Used for products with quick replacement products

- Technical parameter

| Code | Main Technical Parameter | RY-950 |

| 1 | Max Feeding Width | 950mm |

| 2 | Printing Length | 190mm-420mm, |

| 3 | Max Web Width | 950mm |

| 4 | Max printing Width | 920mm |

| 5 | Main Motor Power | 5.5KW |

| 6 | Power Supply | 380V 3PH 50Hz |

7 | Printing Speed | 0-60m/Min |

| 8 | Paper Thickness | 1.7mm |

| 9 | Paste version tape thickness | 0.38mm |

| 10 | The thickness of the substrate | 180g-420g |

| 11 | Overprint precision | ±0.12mm |

| 12 | Total Power | 30KW |

| 13 | Machine dimension | 3*2.8*1.7m |

| 14 | Machine weight | About 5.5 ton |

- Model NO.:

- flexo printing machine

- Embossing Structure:

- Platen Press

- Structure:

- Unit Type

- Application:

- Flexible Packaging Printing

- Automatic Grade:

- Automatic

- Printing Speed:

- 60m/min

- Transport Package:

- Wooden Case

xxxxxx

Best sellers

Your cart is currently empty.